Some time back, Speed channel had an "all around performance car" competition that entailed events like 1/8 mile, auto-cross, slalom and a few other categories. The overall winner was a yellow 72 super.

You can do pretty damn good for a fraction of the cost.

The original front end beams had needle bearings on the outers and bakelite on the inners. Someone (Bugpack?) makes delrin bushings. Try to get ones that are a tight fit into the tubes and snug on the arms so the movement happens at the arm, not the tube. Grease them up good before each event so they don't wear and get sloppy again.

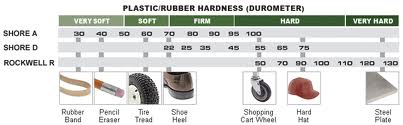

Check the arms for wear on the surfaces they rotate on within the beams. They usually wear on the area where the bakelite bushings were (the inner end). Urethane is, IMHO, not good for that particular application. It is likely about 98 A durometer (durometer or hardness is the measurement of distance a pin with a given surface area will deform the material with a known amount of force).

IOW: they may feel tight by hand but have too much give under the high forces of hard cornering. That's why I recommend delrin bushings. A little wiggle will add up to a lot at the contact patch.

SwayAway makes stiffer torsion leaves for the front but you can modify yours by welding some of them together. Also, lowering the front will help. Adjusters are best; you can also cut-and-turn, but then you are stuck. The top adjuster is for ride and the bottom is for height. Stiffer rear torsions and lowering the back (only slightly, 1 spline) will help too but you have to match them to the fronts.

Upgrade the sway bar on the front and stick a caster shim or two behind the bottom tube so that when you turn, the tire leans into the corner. These are usually used to sorta correct the handling on slammed bugs. To do this, you will need longer bottom bolts.

A kafer brace, urethane spring plate and IRS bushings (I do recommend urethane here), and some sort of down travel limiter (shock straps, welded spacer, etc.) will help tighten up the rear end.

IRS is definitely better. Then you can lower it more and still have good wheel alignment and run a rear sway bar. It's not real expensive, but it is hard to do correctly (welding the top of the bracket) with the body on the pan. The 68 pan is well suited for this type of conversion because it has the straight rear shock tower. The older cars have curved ones that will hit right on the brake line at full compression. If you do it, be sure to use the jigs. The jigs cost $100 but some places will rent them to you (aircooled.net?). It's too easy to screw it up without them.

If you stick with swing axle, your handling will be good but limited and suffer from over steer but a camber compensator will help lots.

Get wide fiberglass fenders and fat tires. The autocrossers in Europe do this with small diameter wheels and tires. Of course, experiment with tires, tire pressure and shocks.

Run a deep sump so you don't suck air and see the idiot light flash or come on steady during hard cornering. This also lowers the CG a bit.

Changing your seats so you sit lower will also help. The driver can easily be 10% of the vehicle weight. Take out any weight up high - radio, wiper motor. Anything you can do to lighten things up will help in both acceleration and handling. Run only 1/4 tank of gas. That gas tank is up kind of high in a bug and it sloshes too.

You can do most this for very little money. The torsion bars, wheels and tires are the spendiest part.

If you do all this stuff you will be in the front half of the pack.

Lower, stiffer, tighter and lighter.